Zero Waste – Zero Landfill for

LAPSSET Corridor

LAPSSET Corridor

PSECC Ltd initiative – Transition into the Circular Economy

Net Zero – Climate Funding

USD $385 Million provided for five plants – All Energy projects within LAPSSET Corridor are to be 30% owned by the Government, as such the Government will be putting in 30% funding. PSECC Ltd can develop these waste plants within the LAPSSET Corridor and pay back the funding from Power Purchase Agreements (PPA’s). 30% Revenue share in each plant back to the Governments within the LAPSSET Corridor.

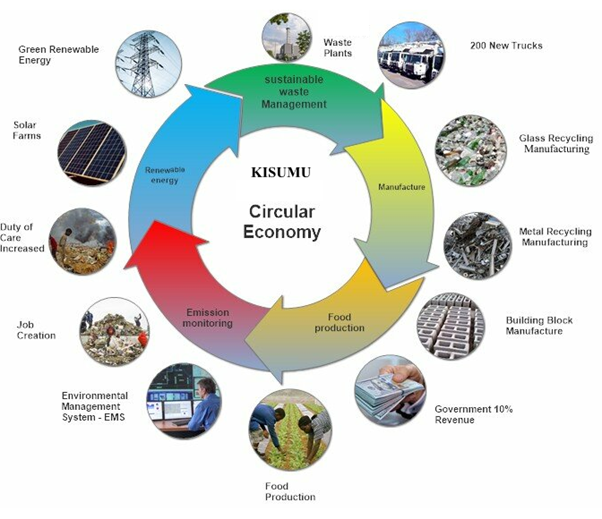

Circular Economy – Sustainable Urban & Rural Life

Transitioning to a Circular Economy

Net Zero – Circular Economy – Climate Funding – Fossil Free Cities

Kenya – The way to Net Zero – Zero Waste & Zero Landfill

PSECC Ltd can provide LAPSSET Corridor in Kenya with these plants and had been considered the best option for Nairobi City in a recent 2023 tender, Ten plants for Kisumu County and seven plants for Kakamega (Kisumu & Kakamega plants have a separate funding package).

We will work with the preferred local engineering partners in Kenya to ensure good delivery of the projects.

In Kenya’s capital city of Nairobi, an estimated 2,400 tons of solid waste is generated every day, 20% of which is in plastic form. Poor waste management, coupled with rising urban pressure, have heightened the risks of environmental degradation in the city of 4.4 million people.

The New Economic Zone could also have our Waste plants & Solar Farms designed into a Sustainable Circular Model for new Cities in Kenya.

50 new trucks for Nairobi & five new plants & full funding provision of USD $385 million. Mo Government funding required and no payback by Government.

Environmental Education Centre

Our EPC partners are Sarralle or Siemens, along with Bio Carbon Fuels offers this proposal to construct the Kenya Environmental Education Centre with the Waste plant incorporated into a Total Recovery Facility® (“TRF®”) inside, which will produce building products from Recycled material and renewable electricity and liquid fuels in the second and third phases of this project.

This project information package is intended to provide Kenya with information regarding a proposed Environmental Education Centre that will convert MSW and other waste streams into composite building products and clean electricity and renewable on-road transportation fuels (the “Project”).

The system proposed will initially consume up to 2,500 tons of MSW currently available in the Nairobi City area. This will eliminate the current practice of landfill saving millions of dollars over current practices. The Project will be scalable to take advantage of future growth opportunities expandable to all the MSW in the including agricultural waste and other various waste streams giving Nairobi 100% reuse and complete recycling with no need for any waste to go to a landfill and reaching the county’s goal of carbon neutral by 2025.

Pollution of land & air

If Nairobi still need plants then Five plants could be built first and operational by August 2028, trucks provided February 2027 followed by other plants throughout Kenya. We will work with the preferred local engineering partners in Kenya to ensure good delivery of the projects. Land contamination and burning of waste leads to pollution – our plants improve the Duty-of-Care for people near sites.

Pollution of Water

MSW plus waste oils, sludge and Medical wastes can be processed in the plants. Waste enters the water and the leachate pollutes. Plastic can enter the Oceans through this and fish stocks decrease in Lake Victoria. Plastic is prevented entering the Lake Victoria and we are working with the LREB in fourteen Counties and hope to prevent further Lake contaimination.

Sustainable Urban Life

Clean Urban Cities can exist with our Sustainable Waste Management plants. New manufacturing & food production for a Circular Economy – leading the way to Fossil Free Cities in Kenya.

USD $385 million – Full funding provided

No Government finance required.

We can clear and use waste from Landfill sites as a mix with normal daily waste generated. Landfill waste increases in calorific value as waste degrades over the years – 23% increase due to organic fraction degrades.

Kisumu will also have $90 million USD for their plant.

No more Landfills – glass is recycled

This recycled glass can be used for new manufactured goods or mixed with ash and cement to make building blocks. There will be no need for anymore Landfill sites – we can also clear old landfill site and use that waste to in our plants. The new Gasification & Recycling plants can now assist the County Government.

Increased collection rates from Cities, Towns and Villages

Metals are recycled

Recycled metals can be used for new factories to make new goods – Circular Economy in action….

New building blocks for houses

Ash, Glass and cement used for the manufacture of new building blocks for homes or ash and glass can be used for road surfacing

Food Production using CO2 from plants

Tomatoes and other crops can be grown in Green Houses close to the plant and using the waste carbon dioxide

Renewable Electricity

Clean Green energy for the transition into Net Zero

There will be no need for anymore Landfill sites

The need for Landfill sites to close. Many of these waste pickers can be given jobs in driving, waste collection or as labourers, technicians and general staff for the new plants

There will be no need for anymore Landfill sites

The need for Landfill sites to close. Many of these waste pickers can be given jobs in driving, waste collection or as labourers, technicians and general staff for the new plants

ZWT – ZERO-Waste Technology for Kenya

Sustainable Urban & Rural living….. We deliver Service functionality, Natural value, adaptive capacity, effective EMS software system and regenerative Circular model. ZERO Waste – ZERO Landfill for Kenya. We have over 100 years expertise in waste management, twenty-six years in Climate Change Mitigation and our EPC company to build the plant is Siemens with over 1,000 Power Plants they have built globally.

200 to 300 JOBS CREATED PER PLANT.

Full funding provided, infrastructure, trucks, Rickshaws for village, Town and City waste collection, also bins and containers. Five plants built first and operational by August 202 followed by other plants throughout Kenya. Funding of $385 million for Nairobi plants via Private Bank @ 6% interest or US Exim Bank @ 5.5% interest rate & Standard Chartered Bank rate 6%.

“NO” Cost or burden to Government for the plants and “NO” Tipping Fee, Renewable Electricity & PPA with Nairobi City to assist the Sustainable Urban & Rural Sustainable Waste Management in the City and Counties of Kenya.

An NDA & Memorandum of Engagement (MoE) has been signed with us and Kisumu County Government and soon a Memorandum of Understanding (MoU) for the ZERO waste ZERO landfill & 100% recycling plant once the official Tender process has been completed. We are the preferred bidder for Kakamega.

A full list of Government Waste reports and Policies together with University Waste Reports can be viewed at the bottom of the “About” page.

Our research on kenya waste indicates this is a project sustainable for the Government and a bankable project that makes the Private Bank funding possible and fits into their strategic objectives. Plants under development in Mexico City, Zambia, Philippines. soon in Nigeria and operational in the USA.

ZERO waste ZERO Landfill – We eliminate the landfill so no waste goes to the landfill. The Landfill waste is also mixed with daily waste generated as a mixed feedstock into our plant. Over time the Landfill site is cleared.

Electricity is produced and 100% Recycling of glass, metals, ceramics and ash.

We hope this fits into the Kenya Government Strategy and meets the objectives of the new Waste Management Facility. The 50 trucks & 100 Rickshaws can be made available to Nairobi approximately two months after funding documents are signed so additional waste can be taken to the Facility and then when he Gasification plant is operational used to take waste to the plant.

We are ZERO waste and ZERO landfills.

A Sustainable ZERO-waste to Landfill – negotiations underway with Government.

Description of Project: Five new Gasification plants

Kenya is a Country with some of the highest Environmental Legislation, our technology has the lowest emissions & highest electricity generation and we offer ZERO Waste & ZERO Landfill & full funding.

Nairobi generates 2,500 to 2,700 tonnes per day (tpd) of MSW, Kisumu City our research indicates 500 tonnes per day of MSW is generated our Gasification & Recycling could produce 671.54 KWh per tonne of MSW = 112,482 MWh of electricity each year from each plant, we suggest five plants are built in the phase one of the development programme for Nairobi.

Kisumu County generates about 5,720 tons of solid waste per day (as per Kisumu-County-CIDP-II-2018-2022-3), which once collection rates increase then a further ten plants could be possible in a phased additional $735 million development programme.

Kisumu City in 2017 generated approximately 400 tonnes of solid waste per day now over 500 tonnes per day, 20%-25% of which is collected to the open dump site. Of the total municipal solid waste that is collected, 65% is organic and another 27% is recyclable (County of Kisumu, 2015). The collection and handling of municipal solid waste poses a significant challenge in Kisumu City. The closure in August 2019 of Kachok dumpsite within the city compromises any progress made in the solid waste management system.

We have been in negotiations with the Governor’s team of Kisumu regarding our assistance in Sustainable ZERO Waste for Kisumu. This has been a one year PPP development programme so far and Governor’s support letters now being applied for and continued negotiations are still in progress.

Following on from the discussions in the zoom call meeting with you and your teams we are going to concentrate on getting ”ONE” plant built first and operational approximately July 2022 and $80 million funding provision. Once the plant is operational and collection rates increase for the MSW we could then consider a second plant and this will be determined during Feasibility Studies.

Our in country partner is Syscraft Limited who are in June 2021 currently negotiating with Governor in kisumu are underway.

In kisumu County for example the Governor supports our project for the plant could be possible – Kisumu generates 500 tonne per day (tpd) of MSW and we could site one plant in the County, if we collect a further 500 tpd it could be possible for two plants at a later date. We will provide $90 million for the Kisumu project and 50 trucks and 100 Rickshaws to collect waste from the City, Townships and villages and we will investigate this potential.

ZERO Waste to Landfill – this means the current landfill site at Kachok will be cleared and waste used as a mix with normal daily waste generated and collected with the fifty new tucks. Waste pickers at Kachok can also be paid to bring plastic and tyres to our new plant. 300 jobs created in Kisumu for the first plant and depending on outcome of full feasibility studies a further plant and more jobs could be the outcome in time.

In our Kisumu plant we will also have Polytunnels for food production utilising the CO2 from the Gasification process, food to be used for feeding the poorer people in a community and for local markets.

This proven, operational technology processes the MSW from the Cities, Towns & Villages together with Landfill sites without any sorting, it all just goes into the gasification system. We also provide all the infrastructure requirements for each plant of 50 Trucks & 100 Rickshaws for Sustainable Urban Living in Kisumu.

Many Sustainable Development Goals (SDG’s) will be met in this project.

Having no need to sort the waste is a big labour-saving step that is eliminated from the process. 100% Recycling of metal, glass and Ceramics is possible and using the plastic in energy recovery to increase Kisumu’s Green Energy. The Energy recovery technology is Gasification, there is the lowest air pollution and NO ground water contamination & ZERO to Landfill from our Gasification & process.

Kisumu produces 500 tonnes per day (tpd) of MSW and the remaining 500 tpd of MSW for a second later plant in time can be obtained from the landfill sites, other regions of Kisumu and possibly Lake Victoria and this will be investigated once the first plant is operational.

This Gasification technology has received the highest rating from the Environmental Protection Agency (EPA) in the USA for the cleanest process system for MSW treatment, cost effective, sustainable, proven technology and comes with full Bilateral PPP funding.

Recycling & Manufacturing….

The Gasification process also destroys all the plastic and rubber from tyres, rendering the remaining final products as 100% inert. Because of the need for more Green electricity in Kisumu it is better to use this plastic in energy generation in our plants to provide “Base Load” electricity.

People will be paid to bring additional waste to the plant. The end products from this process are 10 tonnes of glass, ferrous metals and non-ferrous metals10 tonnes per day from each plant, which are then recycled together with 10 tonnes of ceramics and ash.

The glass and ceramics are then ground and added to concrete along with the ash for the production of concrete blocks, NOTHING remains for landfill.

Gasification is very clean and 45% more efficient than Incineration. Our EPC Company that will build the plant is Siemens. 100% Recycling with Gasification electricity production & Recycling for Kisumu City.

ZERO Waste – ZERO Landfill – 100% Recycling, Reuse, Recovery, Reduction